We are an environmentally conscious and innovative company

ABOUT UZIMET

Purified and customized

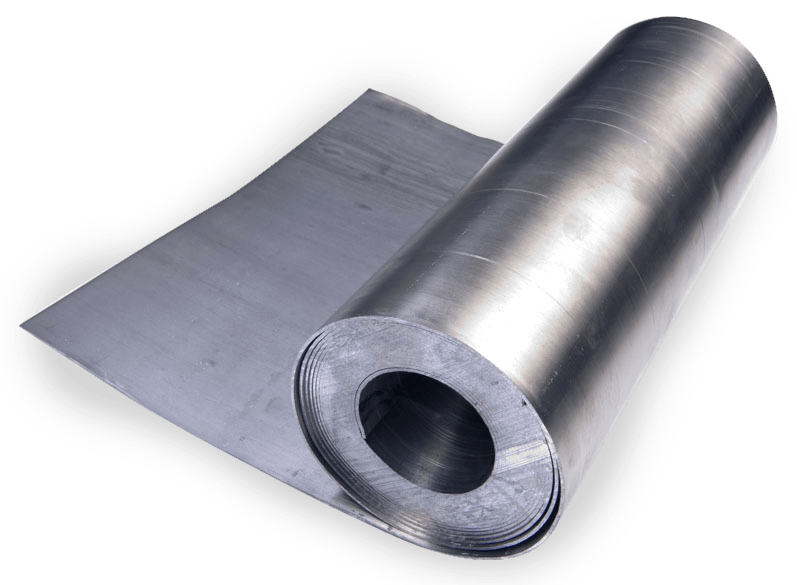

100% of lead sheet used by Uzimet comes from recycled material, none from primary mining sources! Our lead is produced on the basis of scrap which is supplied by metal traders. After a quality check, the old lead is melted down. Residual materials that are not suitable for Uzimet to make new lead from are sent to recycle processing companies. They convert these into metals such as brass, zinc, tin, lead, antimony and iron. Uzimet refines the liquified lead by removing impurities. Copper is also added to make the rolled lead comply with NEN-EN12588. Ultimately, a block of lead is created, which is processed into plates and coils in our rolling mill.

Assortment and markets

Uzimet’s core business is lead sheet, we have been making this since the 1800’s and this is where our expertise lies. We use two rolling mills, each with its own unique properties.

Our lead is mainly used in construction as lead flashing in the cavity wall, under a skylight or chapel and to make a chimney watertight.

Due to the high density and specific weight of lead, lead is not only a protection against water ingress, but also the perfect material as an application to block radiation and as ballast. Lead is an indispensable material in hospitals, dental practices and rooms with radioactive radiation.

Even where space is limited, lead offers an effective solution, examples are counterweights in sawing machines, bridges, and the keel of a boat.

Perfectly recyclable

In whatever form our lead sheet is processed, it remains an almost perfectly recyclable material. For example, your lead sheet may have been on a cathedral centuries ago and will easily serve another hundred years on a town hall. Practically nothing is lost in this virtually closed cycle. Within our production we can also reuse all cutting and sawing residues in the melting process. The environmental performance of lead sheet is much better than alternative, water-retaining materials in construction. A Life Cycle Analysis by TNO has proved this.

Calder Group

Our strong market position and excellent outlook are certainly also due to the fact that we have been part of the internationally operating Calder Group since 1994. The cooperation within the Calder Group extends to mutual support in the field of production, raw material purchase and deliveries to our international customers.

LEAD SHEET_

Can be imitated but not

matched!

Any shape possible

Lead is a soft and flexible metal that is easy to form and shape.

Unlimited recyclable

Lead has the highest recycling percentage of all metals, more than 95% of scrap lead is collected and recycled – no lead goes to landfill.

Durable

Lead has a proven long lifecycle <50 years is rather the rule than the exception. With a low melting point of 327°C, lead has one of the lowest energy demands of any metal and lowers the cost of recycling. Because of lead’s low melting point the process of recycling is very energy efficient, requiring approximately one-third of the energy involved in winning lead from its ore. A sustainable and circular material.

Valuable

Due to the usefulness of old lead, it always retains its value and does not end up in the environment.

CERTIFICATES

The highest standards of environmental management and employee health and safety.

We are committed to the maintenance of a quality management system (QMS) that conforms to the requirements of ISO 14001, ISO 45001 & ISO 9001 (Environmental, Occupational Health and Quality Management System)